- Home |

- FRP Blowers

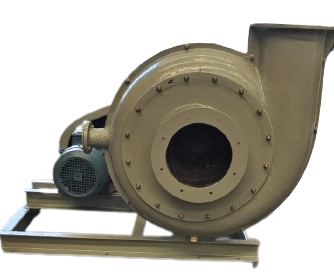

FRP Blowers

Corrosion-Resistant Air Handling Solutions for Industrial Applications

Corrosion-Resistant Air Handling Solutions for Industrial Applications

FRP (Fiberglass Reinforced Plastic) blowers are specialized air-moving devices engineered for corrosive environments, where conventional metal blowers would fail due to chemical exposure and degradation. Constructed from high-strength fiberglass and chemical-resistant resins, FRP blowers provide safe, efficient, and long-lasting air handling performance.

Key Features & Benefits

Corrosion Resistance

Designed for harsh industrial settings, FRP blowers offer superior resistance to acidic fumes, chemical vapors, and corrosive gases, ensuring long service life even in aggressive conditions.Lightweight & Durable

Despite their robust performance, FRP blowers are lightweight, allowing for easier transportation, installation, and maintenance compared to metal alternatives.Customizable Configurations

Available in a wide range of sizes, flow capacities, and pressure ratings, FRP blowers can be tailored for:Air supply or exhaust systems

Fume extraction

Ventilation in chemical process areas

Optional Features

For enhanced performance and safety, units can be equipped with:Variable speed drives (VFDs)

Explosion-proof motors

Acoustic enclosures

Anti-vibration mounts

Applications

FRP blowers are ideal for industries where air purity, equipment longevity, and resistance to corrosive media are critical:

Chemical processing plants

Wastewater treatment facilities

Pharmaceutical and biotech manufacturing

Fume hoods and scrubber systems

Laboratory exhaust systems

Why Choose JMZCEL FRP Blowers?

At JM Zhongkai Chemical Equipment LLP, we design and manufacture high-performance FRP blowers using advanced composite materials and precision engineering. Our products are built to deliver consistent airflow, chemical resistance, and trouble-free operation, even under the most demanding conditions.

FAQs – FRP Blowers

1. What makes FRP blowers suitable for corrosive environments?

Answer:

FRP blowers are constructed from fiberglass reinforced with chemical-resistant resin, offering exceptional protection against acids, solvents, fumes, and other corrosive agents. This makes them ideal for handling hazardous gases in chemical and industrial environments.

2. Can FRP blowers handle high-temperature gases?

Answer:

Yes, but within limits. The temperature resistance of an FRP blower depends on the type of resin used in its construction. For higher temperatures, specialized high-temperature-resistant resins can be used during manufacturing.

3. What airflow capacity do FRP blowers offer?

Answer:

FRP blowers are available in a range of airflow capacities, from a few hundred CFM (Cubic Feet per Minute) to tens of thousands of CFM, depending on the application and design specifications.

4. Are FRP blowers customizable for specific applications?

Answer:

Absolutely. JMZCEL offers custom designs tailored to project requirements, including specific airflow, static pressure, ducting connections, and motor specifications such as VFDs or explosion-proof ratings.

5. How do FRP blowers compare to metal blowers in terms of maintenance?

Answer:

FRP blowers require significantly less maintenance than metal blowers, as they are immune to rust and chemical corrosion. Routine inspection and basic cleaning are generally sufficient for long-term performance.

6. Can FRP blowers be used in explosive or hazardous areas?

Answer:

Yes. FRP blowers can be fitted with explosion-proof motors and other safety features, making them suitable for use in ATEX-rated zones or hazardous chemical environments, depending on the project’s safety requirements.